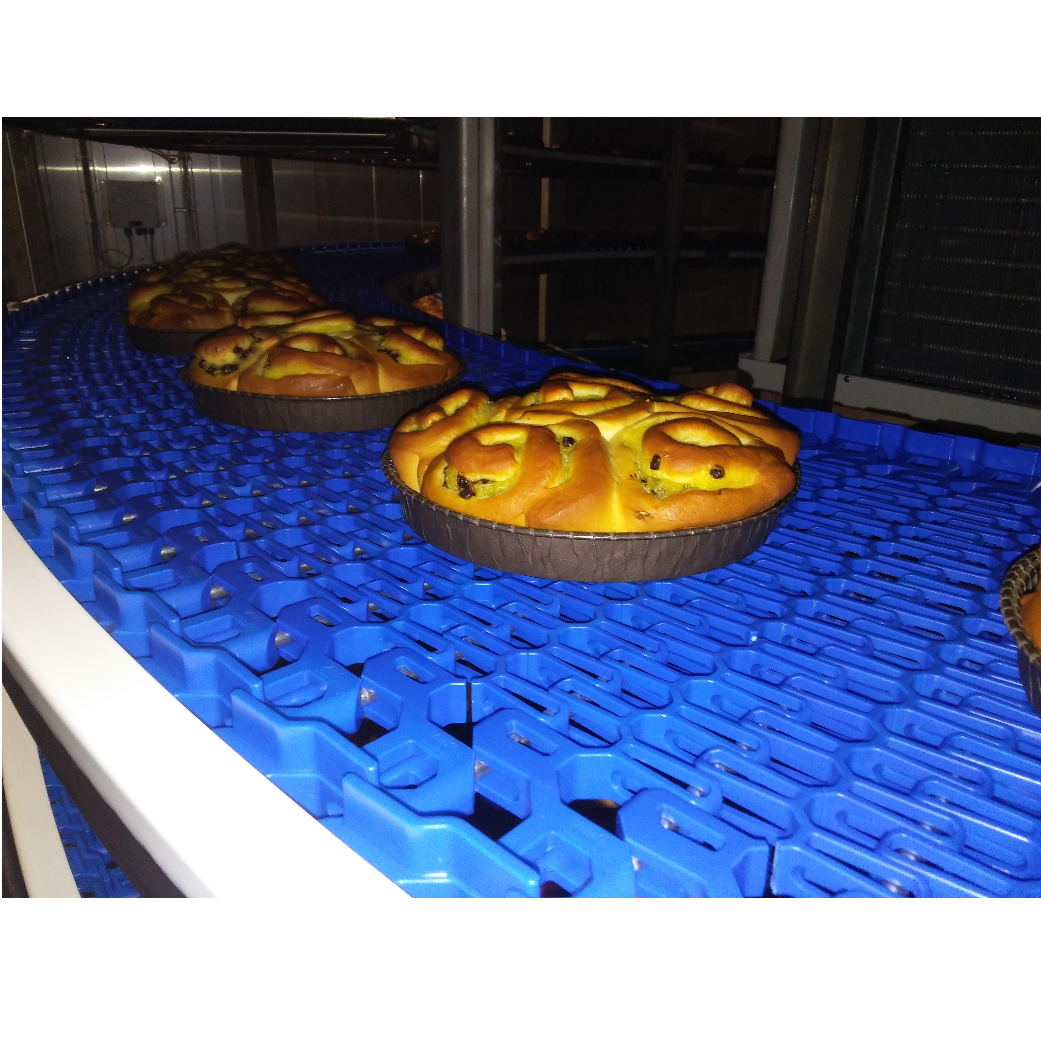

Spiral leavening system

General Processing Technology

Information

The Sarp spiral leavening system allows an optimum temperature of up to +40 °C for dough growth. The conveyor belt runs vertically in a spiral shape, minimising floor space requirements.

The leavening equipment is positioned inside an insulated cell where the humidity percentage is monitored, regulated and kept constant.With SARP you have the opportunity to customise the spiral leavening unit, both in terms of shape and functionality to better suit your production needs. Thanks to our many years of experience, we offer a service that includes: a site inspection, study, and analysis of the product characteristics, the design of the most suitable solution and the creation of leavening spirals that can optimise your production line. We support you with a common goal: reducing costs and time.

Thorough cleaning is enabled by easy access to the machine components, ensuring a clean product. Sarp also offers you the possibility of equipping your production circuit with an airtight cell for high-pressure sanitisation.The Customer Service team accompanies you every step of the way: from on-site installation, to assistance in the event of any critical issues in order to guarantee high machine performance at all times.

Product list:

Round bread

Baton Bread

Pizzas

Croissants

Rusks

Pancakes

Biscuits

Patisserie products

Cakes

Cream filled cakes

Desserts

Ginger Bread

Pryaniki

Sushki