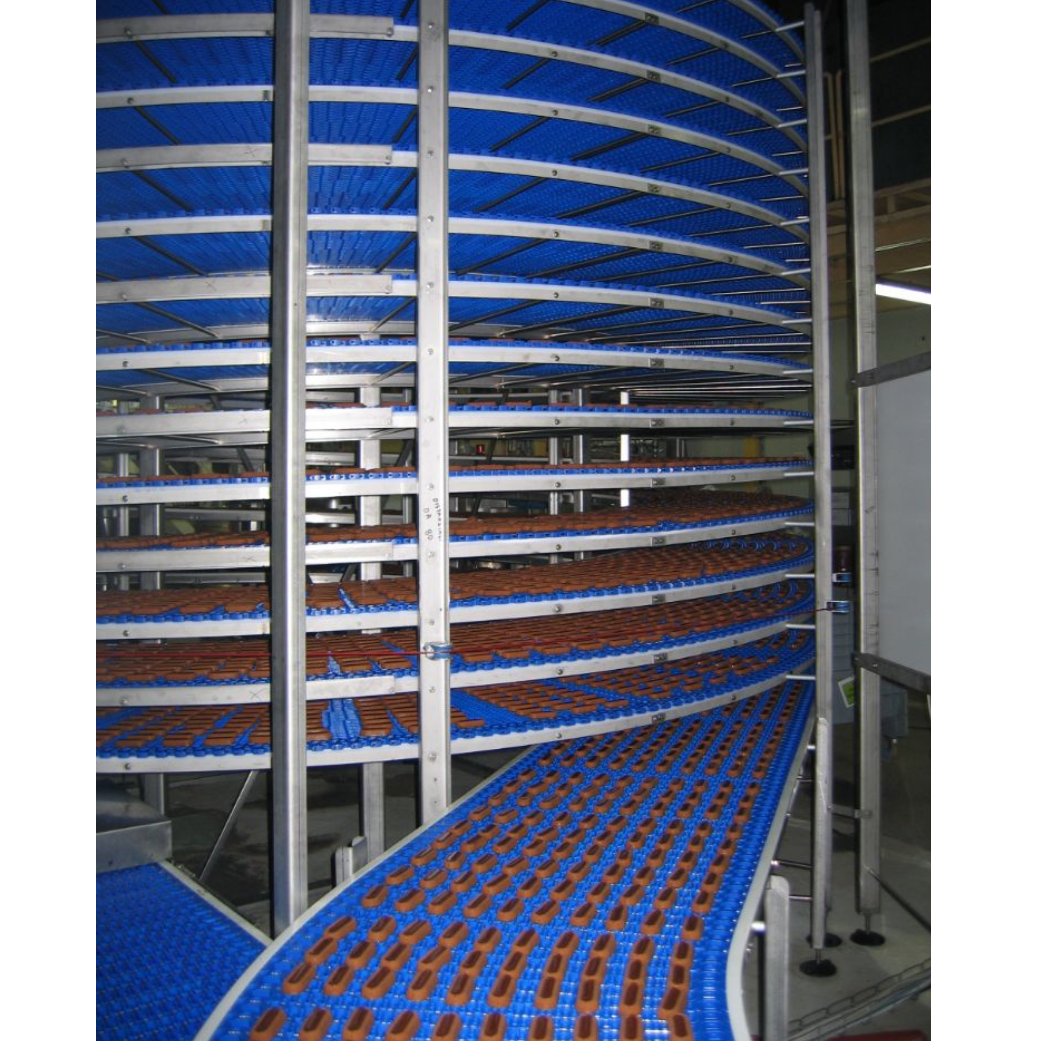

Cooling lines for bakery products

Bakery Equipment & Supplies

Information

Conveyor belts for processing bakery products

Sarp's bakery conveyor belts are specially designed for the treatment of baked goods, both loose and packaged. The available functions are effective on different types of dough and are: drying, leavening, sterilizing, pasteurizing, cooling, freezing, and deep-freezing.

Conveyor belts for bread, cakes, pizza, and other bakery products are designed to minimise floor space: the spirals are arranged vertically and pulled by a driving tower, gaining more space in the center that can be used for other treatment devices.Bread freezing spirals produce a thermal exchange between air and product close to 100 percent.

Each machine is tailor-made (which can be oval, round and figure-of-eight) to suit your production needs.Our bakery conveyor belts are equipped with a special type of belt that allows efficient sliding and less wear and tear. You will not need to use greasing, and you will have the certainty of obtaining a clean product.

The belt used for conveying can be of different types, depending on production needs, and is designed to prevent the product from sticking and to ensure that no traces are leftover on the surface.Customising the system to specific needs also opens up the possibility of incorporating product build-up systems, which prevent wastage in the event of machine downtime, thus having a very low product-waste rate.

The frame in contact with the product guarantees maximum hygiene and is designed to facilitate cleaning and routine maintenance.The systems have a lean and dynamic structure, which avoids possible accumulations of flour and dust. The spirals for bakery products can work in air and ambient, or inside isolation cells, which allow the products to be processed at an optimal temperature, which is kept constant, with a flow of air that dries the products and reduces their moisture.

Customisation and reliability are the guarantees