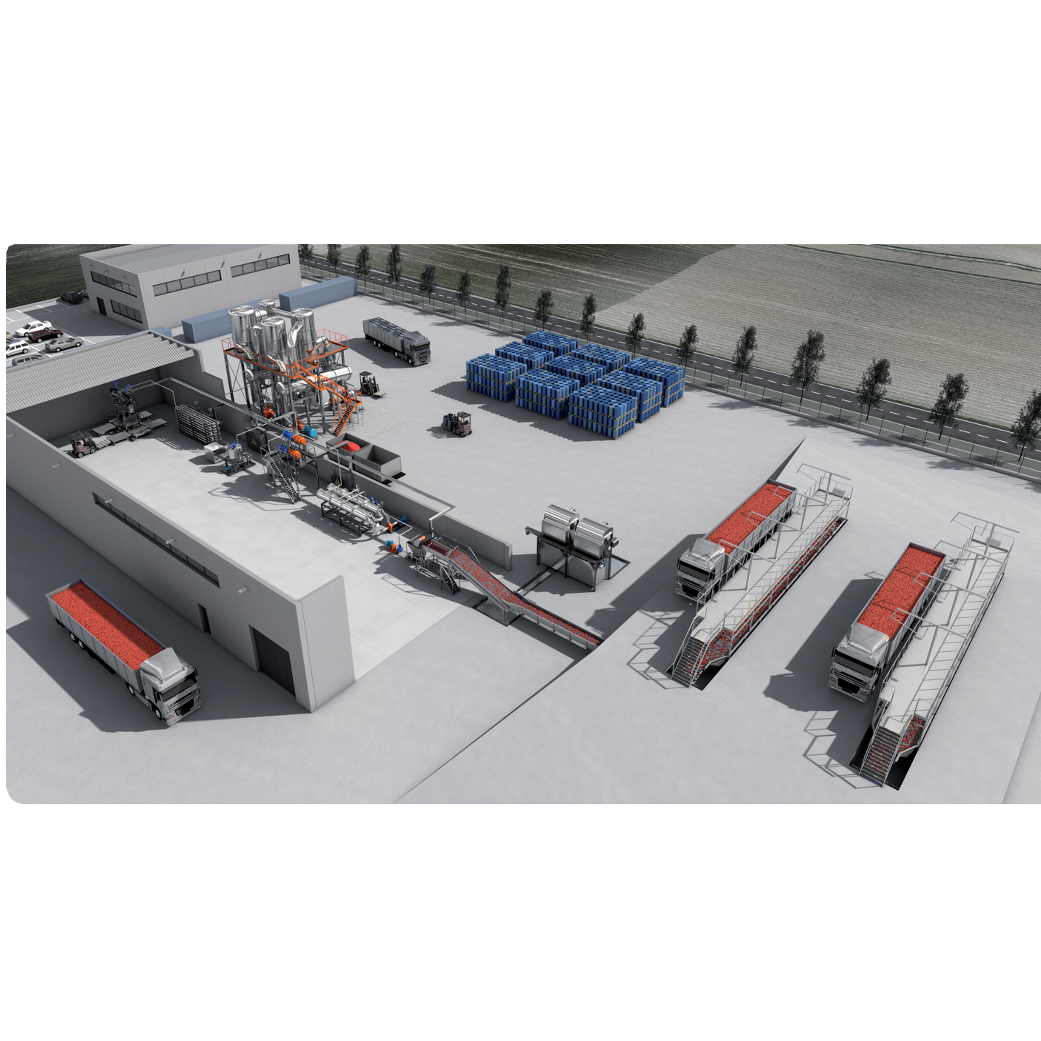

TOMATO PROCESSING LINES

General Processing Technology

Information

In order to obtain an excellent final product, particular attention must be paid to the receivingand sorting phase of the incoming fresh tomato, before being sent to the processing section.The raw material coming from the harvesting areas is transported by truck, by bins or case.Tomatoes can be unloaded into the feeding channels by bin dumpers or case dumpers, or directlyfrom the trucks through the use of water spray nozzles.An energetic washing, done with a shower system mounted on a roller elevator, guaranteesmaximum cleaning.

It is possible to install an automatic scraping system (redler) to eliminate mud, stones and otherimpurities that accumulate on the bottom of the feeding channel, as well as a system to filter the recirculated water, which allows to keep the water in cirlculation free from solid deposits.After the washing, the incoming tomatoes are transported towards the sorting tables throughappropriate channels and finally they reach the optical sorter, which allows to eliminate anyresidual presence of foreign bodies.FBR ELPO’s lines have operating capacities ranging from 5 t/h to 100 t/h of fresh incoming product.