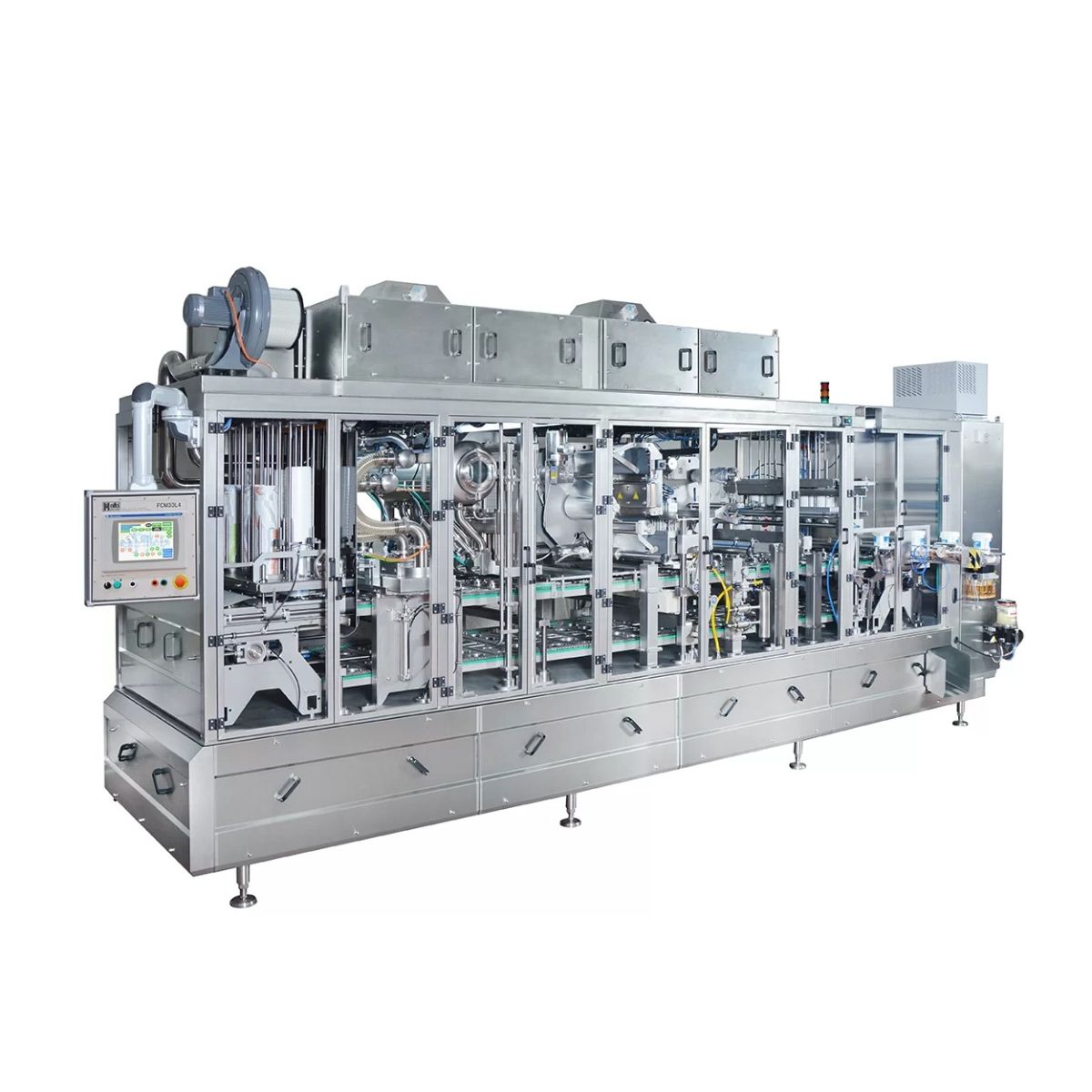

Advanced Ultra-Clean Fill-Seal Machine for Cups

Filling And Sealing For Preformed Packaging

Information

Linear Fill-Seal machines, capable of a large volume production output. Appropriate for single cups, split cups, cups with snap-on lid, small buckets and tubs, give the benefit of integrated state-of-art sterilization equipment for advanced hygiene. Suitable for semi-viscous products such as yogurt, cream, butter, jam, honey, chocolate paste, sauces and many more.

Production capacity up to 18000 cups per hour.

Key Features:

Easy changeover for different size cups.

Filling volume range: up to 1L.

Easy to operate and maintain with

improved ergonomics.

Servo-motor driven chain cup conveyor

for spill avoidance.

Servo technology employed in every machine station.

Automatic destackers and feeders for containers,

pre-cut lids and snap-on rigid lids.

Refeeding of packaging materials without machine stop.

Container discharge on one or two conveyor belts.

Seal integrity check by mechanical squeezing

or thermal treatment.

Maximum flexibility and user-friendly interface of HMI.

Remote diagnosis and maintenance provided by secure cloud technology.

Options:

Ultra-Clean hygiene level equipped with:

Laminar flow cabinet with class 100 clean air

overpressure consisting of:

Coarse dust filter (G4)

Fine dust filter (F9)

HEPA (High Efficiency Particulate Air) filter H14.

UV-C system (up to LOG4) for lid film sterilization.

Pulsed-UV light (up to LOG3) for containers and pre-cut lids sterilization with air-cooling unit and output up to 700 J/pulse, at a frequency of 3 Hz.

Total DNA destruction.

Rapid sterilization.

Low heat generation with short pulse & high peak energy.

Free of toxic substances compared to mercury UV lamps.